Nags Head Lane (Brentwood) STW is a medium sized, biological filter type sewage treatment works facility, serving a population equivalent (PE) of 36,500.

The main scope of the project is to extend the treatment capacity and improve discharge quality standards of the site to enable it to treat an increased volume of incoming flow.

The site has been identified under the Wastewater Quality NEP5 programme which includes quality drivers for revised Ammonia and BOD consents to be achieved by March 2020. The purpose of the revised discharge consent is to improve the quality of the final effluent entering the local watercourse to help improve aquatic plants and wildlife.

Additionally, the expected population growth exceeded the site capacity, the growth scheme works has seen upgrades to meet the 2026 design horizon.

The upgrade works include:

- Convert the existing Balancing Tank to a Primary Settlement Tank (5 No. in total)

- Provide new desludge pumps and actuated valves for the new PST.

- Construct two new Percolating Biological Filters complete with distribution and collection chambers.

- Construct a new Recirculation Pumping Station and decommission existing recirculation pumps within the TT Feed Pumping Station.

- Construct a new Humus Tank (half-bridge scraped type) adjacent to existing three Humus Tanks, complete with a dedicated desludge pump.

- Modify Humus Tank Distribution Chamber.

- Upgrade and refurbish the existing nSAF Plant for revised FFT.

- Provide new Tertiary Treatment (TT) Plant (Pile Cloth Media Type MECANA Filters) with a Flocculation Tank for future installation of top-entry agitator mixers.

- Construct a new Primary Sludge Pumping Station to transfer sludge from the PSTs into the Picket Fence Thickeners.

- Provide additional new Picket Fence Thickener.

- Provide two additional new Sludge Holding Tanks for increased sludge retention capacity. New SHTs complete with an air mixing blower package.

- Provide new Odour Control System to serve the new PFT and Sludge Holding Tanks.

- Provide new fibre network complete with network node boxes and a Data Concentrator PLC.

- Provide two new MCC’s to accommodate new equipment being installed. The MCC’s are designated as “Sludge MCC 2” and “Main Incomer MCC”.

- Installation of two new GRP fabricated kiosks to house the two new MCC Panels.

- PLC and SCADA Upgrades across the whole site.

Our scope on the whole project included the following services:

- Full development of detailed electronic format Operations & Maintenance Manuals (O&Ms).

- Completion of CDM Health & Safety File.

- Asset Registration.

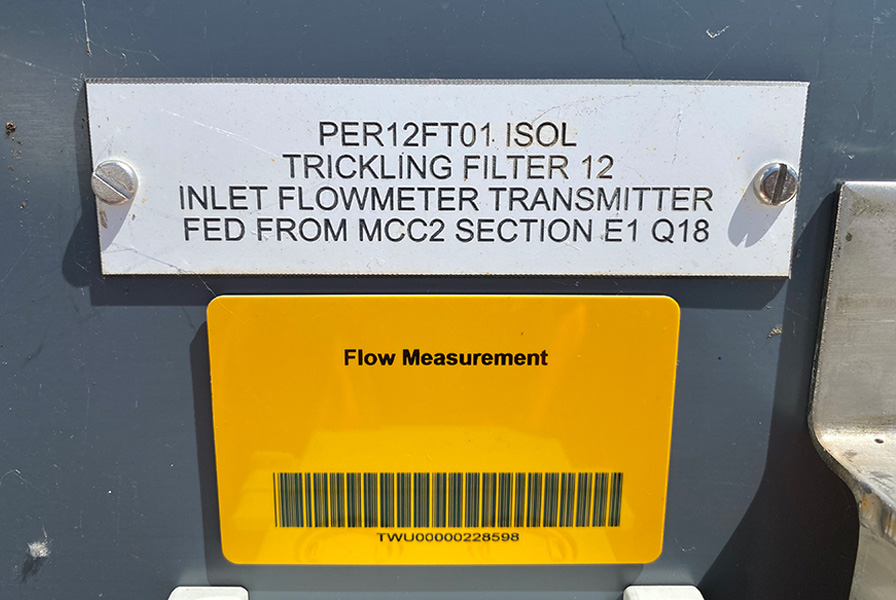

- Onsite Installation of Thames Water Asset Barcodes.

- Liaison and collaboration with all subcontractors involved on the scheme to co-ordinate the required documentation and drawings and ensure full compliance with the end clients specific standards.

- Providing As-Constructed Asset Photographs.

To complete the above services, our project team visited the site multiple times to collect all required information. Throughout the duration of the project we attended numerous progress / handover meetings including meeting Thames Water’s Operations Representatives to discuss technical elements of the documentation.

Throughout the project we worked very closely with SMB JV’s project team including design engineers, handover co-ordinators and project manager to ensure all documentation deliverables were submitted on time and to the required high standard expected.

November 2019 – October 2020

Skanska MWH Balfour Beatty Joint Venture (SMB JV)

Thames Water