A total of 25 sewage treatment work sites across the Thames Water region were upgraded to meet tighter phosphorus consent limits.

3rd Light Media had previously successfully worked on a similar 10-site P Removal programme for Thames Water earlier in the AMP 6 period. We were awarded a long-term contract over 2 years to complete the required handover documents for each individual site across the scheme. This was one of our largest single contracts with a contract value worth over £100,000.

The upgrade works at the sites typically included the following scope:

- Ferric dosing packages including mixing systems.

- Alkalinity dosing (caustic) dosing packages

- Tertiary Treatment Plants comprising of Pile Cloth Media filters.

- Humus Settlement Tanks, complete with Desludging Facilities.

- Sludge upgrades including new Sludge Holding Tanks and associated transfer pumping equipment.

- Effluent sampling instrumentation.

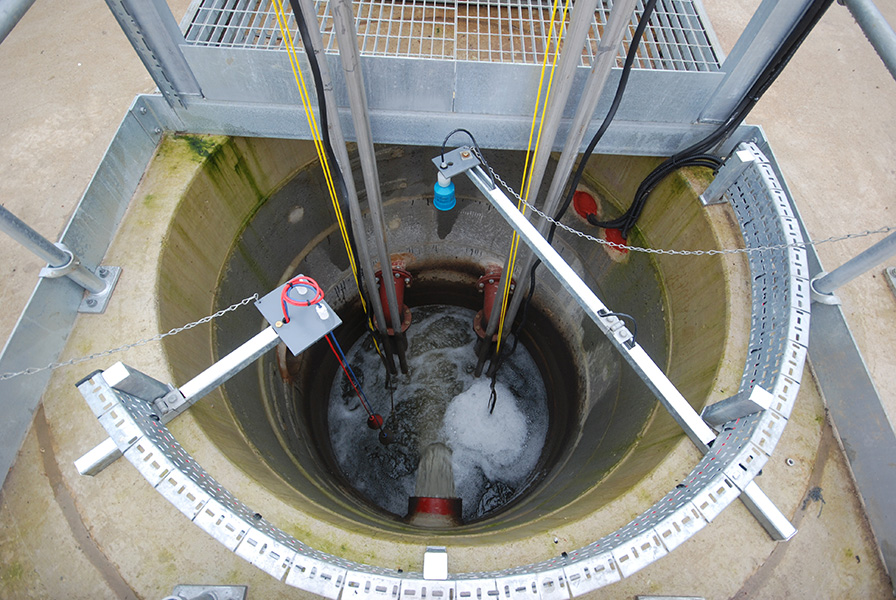

- Works / Liquor Return pumping upgrades.

- Electrical infrastructure upgrades, comprising of new control panels and mains incomers.

- Reed Bed Construction.

Additionally, one of the sewage treatment works on the scheme was decommissioned with the sewage flows diverted to a larger STW in the region. As such, two new Sewage Pumping Stations (SPS) were constructed to pump the flows from the old STW site into the sewer feeding the larger STW. The two pumping stations were brand new sites so had to have full, complete sets of new documentation developed.

Collaborative Approach:

3rd Light Media was part of an integrate team, working closely with the principal contractor (SMB JV) project teams, subcontractors, designers (GHD) and also directly with the end client, Thames Water. Regular collaborative meetings and working methods were used throughout the project to ensure tight compliance deadlines were achieved and all aspects of the required handover documentation were delivered to the highest standards.

Our scope on the whole project included the following services:

- Full development of detailed electronic format Operations & Maintenance Manuals (O&Ms) for each individual site.

- Completion of CDM Health & Safety Files for each individual site.

- Asset Registration.

- Onsite Installation of Thames Water Asset Barcodes.

- Supply and Onsite Installation of Asset Identification Tags and Labels.

- Liaison and collaboration with all subcontractors involved on the scheme to co-ordinate the required documentation and drawings and ensure full compliance with the end clients specific standards.

- Providing As-Constructed Asset Photographs.

To complete the above services, our project team visited the site multiple times to collect all required information. Throughout the duration of the project we attended numerous progress / handover meetings including meeting Thames Water’s Operations Representatives to discuss technical elements of the documentation.

Throughout the project we worked very closely with SMB JV’s project team including design engineers, handover co-ordinators and project manager to ensure all documentation deliverables were submitted on time and to the required high standard expected.

October 2018 – April 2021

Skanska MWH Balfour Beatty Joint Venture (SMB JV)

Thames Water