Affinity Water’s largest water treatment works was upgraded during AMP 6 to ensure it continues to provide a robust treatment solution for the removal of pesticides from water abstracted from the River Thames.

The scope of the project was to increase the granular activated carbon empty bed contact time (GAC EBCT) to a minimum of 15 minutes to enhance pesticide removal. Trant Engineering was appointed as principal contractor and teamed up with AECOM for the provision of 8 No. new GAC filters, clean backwash tank and pumping station, high voltage works, increased sludge storage and associated equipment. The (circa) £12m project started construction in January 2017 and was completed in July 2018.

The main scope of the works delivered under the project was as follows:

- Construction of 8 new GAC Filters designed for a normal flow rate of 63.5 Ml/d and an emergency peak flow rate of 120 Ml/d.

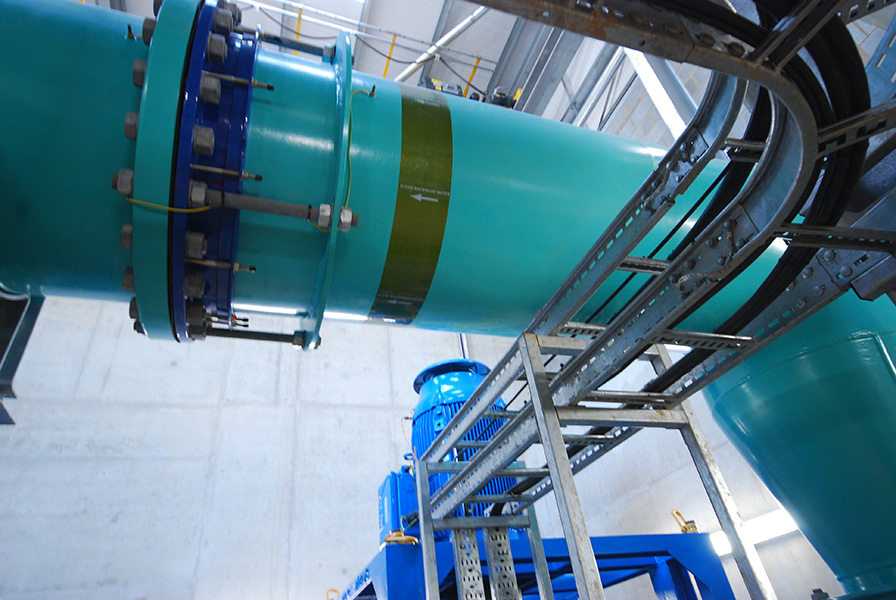

- The backwash system used for the existing GAC filters did not have sufficient capacity for the new GAC filters. Therefore, as part of this project, it was necessary to construct a new backwash system including clean backwash water storage tank, backwash pumps, air blowers and associated equipment.

- Construction of a new Sludge Holding Tank to handle the increased GAC backwashing flows including jet mixers and actuated penstocks.

- New MCC Panel and modification to existing MCC’s. Upgrades to the sites HV network.

- Local operator console and integration with existing SCADA fibre optic network with modification to the SCADA server for the new plant and equipment.

Our scope on the project included the following services:

- Full development of Operations & Maintenance Manuals including dynamic online web-based manuals.

- Supply & Onsite Installation of QR Coded Asset Identification Tags. The QR Tags allow for integration with Affinity Water’s asset management system as well as the dynamically developed site documentation (O&Ms).

- Design and manufacture of a large process graphics board, showing the GAC process and site flows as a graphical representation to clearly illustrate the process and how the new treatment streams work.

- Provision of AutoCAD drawings (Site Plan, Process Flow, Single Line Diagram) under a direct contract with Affinity Water.

- Completion of the Health & Safety File.

- Asset Registration on Affinity Water’s Asset Management Database.

- Completion of the Training Manual.

- Supply & Onsite Installation of Pipe Banding.

- Liaison and collaboration with all subcontractors involved on the scheme to co-ordinate the required documentation and drawings and ensure full compliance with the end clients specific standards.

Throughout the project we collaborated closely with both Trant Engineering and Affinity Water to ensure the documentation was completed on time as per the key milestones on the project and to the required high standards expected.

February 2017 – July 2018

Trant Engineering Ltd. / Affinity Water

Affinity Water