The site treats water from an open storage reservoir which is replenished by transfer pumping from the River Eden.

Bough Beech’s treatment train comprises clarifiers, rapid gravity filters (RGF), granular activated carbon (GAC) adsorption, trihalomethane (THM) stripping, ultraviolet (UV) and chlorination disinfection. Treated water feeds three service reservoirs.

A three-phase programme of enhancements at Bough Beech will ultimately increase the capacity to 70Ml/d.

Phase 1 enabled the plant to output its full design capacity of 45 Mld, to provide additional GAC contact time and in addition provide UV treatment for cryptosporidium protection.

Phase 2 provided a new RGF filter block and upgraded the GAC and THM plants. In addition, the sludge treatment plant was upgraded to meet the works’ increased throughput. The site output following completion of the phase 2 works raised capacity from 45 to 50Ml/d.

Phase 3 will ultimately see the works upgraded to reach the full designed 70 Mld output.

Bough Beech, near Edenbridge, Kent

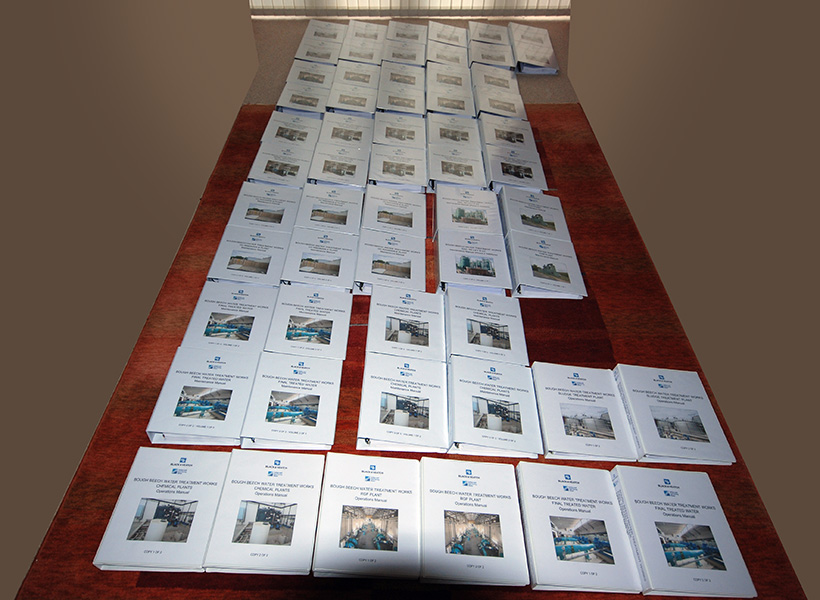

Operations and Maintenance Manuals and Onsite Support Services

As part of the Phase I refurbishment we produced full Operations and Maintenance Manuals for the following process areas

- Raw Water Inlet & Clarifiers

- GAC Filtration Plant

- Re-Lift Pumping and UV Disinfection

- Washwater

As part of the Phase II refurbishment we produced full Operations and Maintenance Manuals for the following process areas

- RGF Plant

- Sludge Treatment Plant

- Final Water Pumping Station

- THM Plant

- Standby Diesel Generators

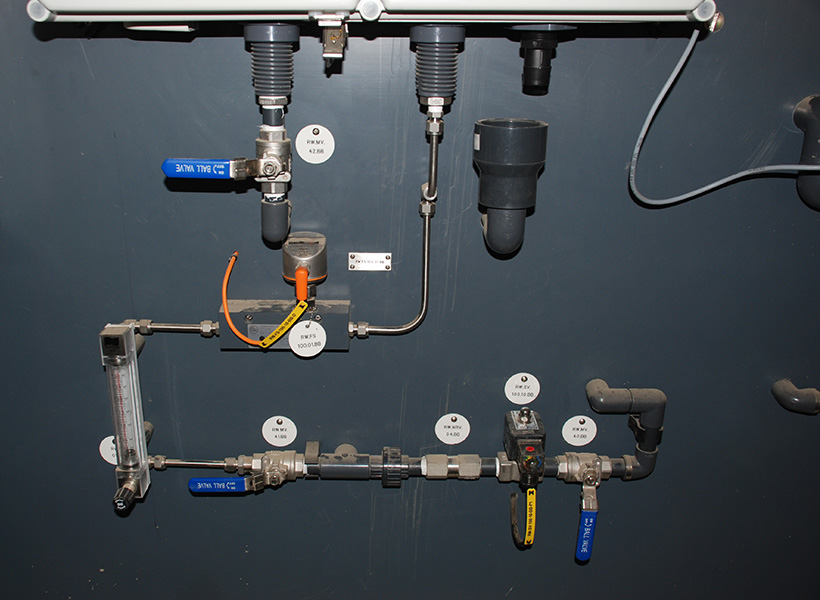

- Chemical Dosing Systems

Onsite Support Services on both phases included:

- Installation of Asset Identification Tags

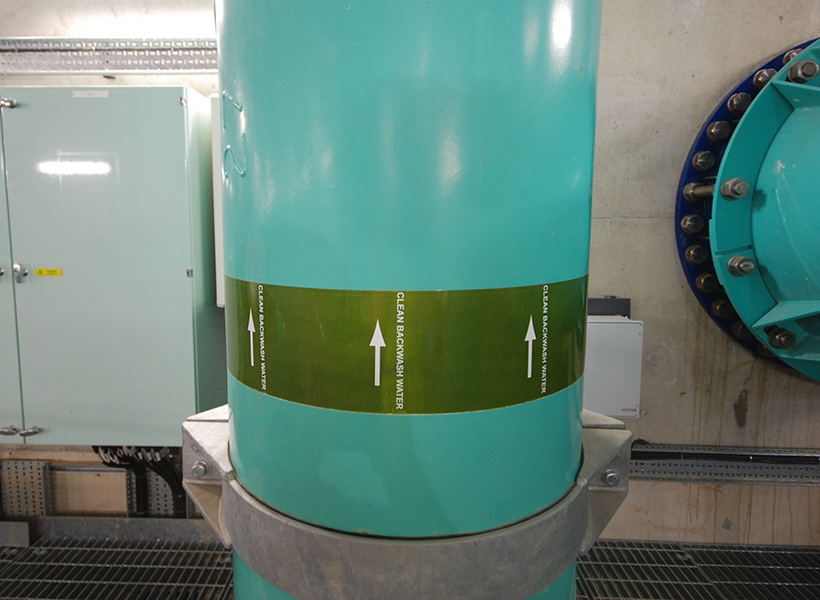

- Installation of Pipe Banding

- Installation of General Site Signage

Black & Veatch